Slug Catchers

Slugging refers to the irregular two-phase flow of both gas and liquids in a gas pipeline. Slug flow can create serious issues in gas pipelines and facilities including severe damage from mechanical vibrations, reduced production and even forced shut down of separators and compressor stations. As a result, having the capability to handle and mitigate the issues created by liquid slugs should always be a high priority in gas pipeline and facility design considerations.

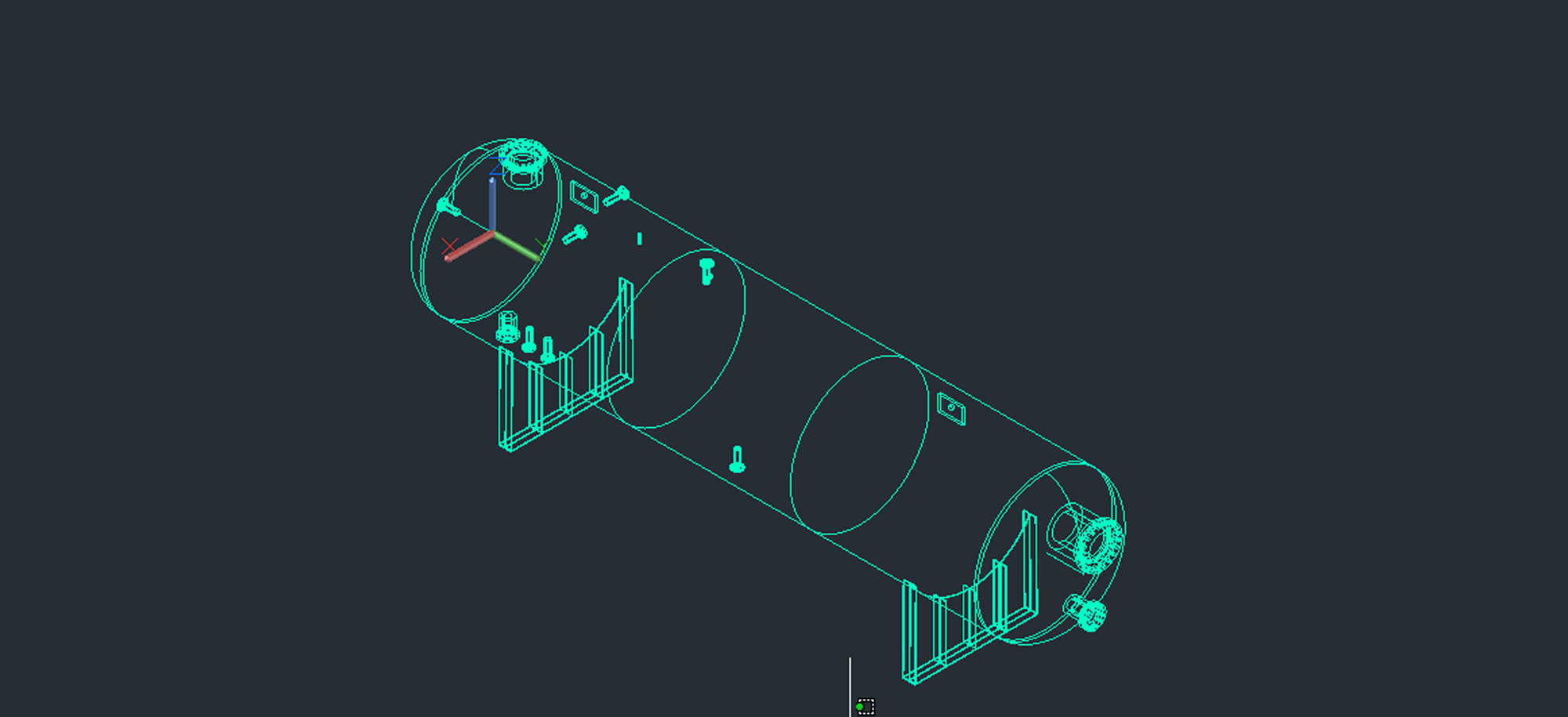

Vessel-Type Slug Catcher

Spitzer’s Slug Catchers are designed in both the Two-Phase and Three-Phase variations. Both variations are in the most economically feasible way to handle the two-phase gas-liquid slugs. For many applications a vessel-type slug catcher is enough to capture and process, or work off the slug, without causing an upset at the facility. In this application the slug catcher works as a simple separator, with sufficient space to hold the liquid slug while still allowing gas volumes to pass unrestricted in the upper section of the vessel.

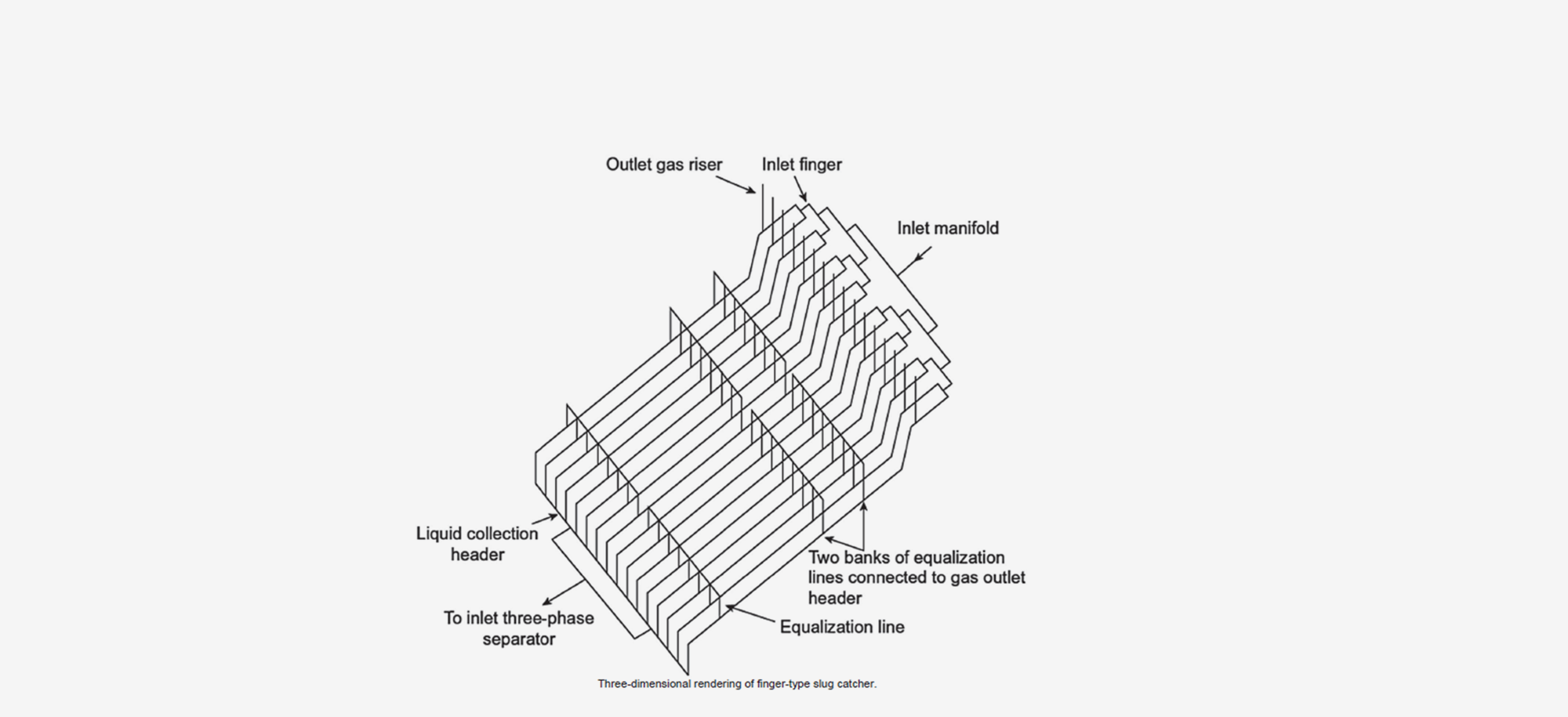

Finger-Type (Harp) Slug Catcher

When liquid volumes become sufficiently large, it becomes more economical feasible to use the Finger-Type slug catcher, this is due to the thinner wall requirements for the smaller diameter pipe or fingers. In addition, the manifold style of a Finger-Type slug catcher allows for easy addition of additional pipe should more capacity be needed in the future.

- Available with pneumatic controls to be installed in remote locations with or without power.

- Available in a skidded package to with all instrumentation for ease of install, or as bare vessel.

- Available as Three- or Two-Phase variations.

- Available with internal mist extractor or vane pack in order to meet customer specification.

- Spitzer’s Standard Slug Catcher can be designed to accommodate expansion with minimal shutdown time.